Services

Product Quality and

Safety Management Systems

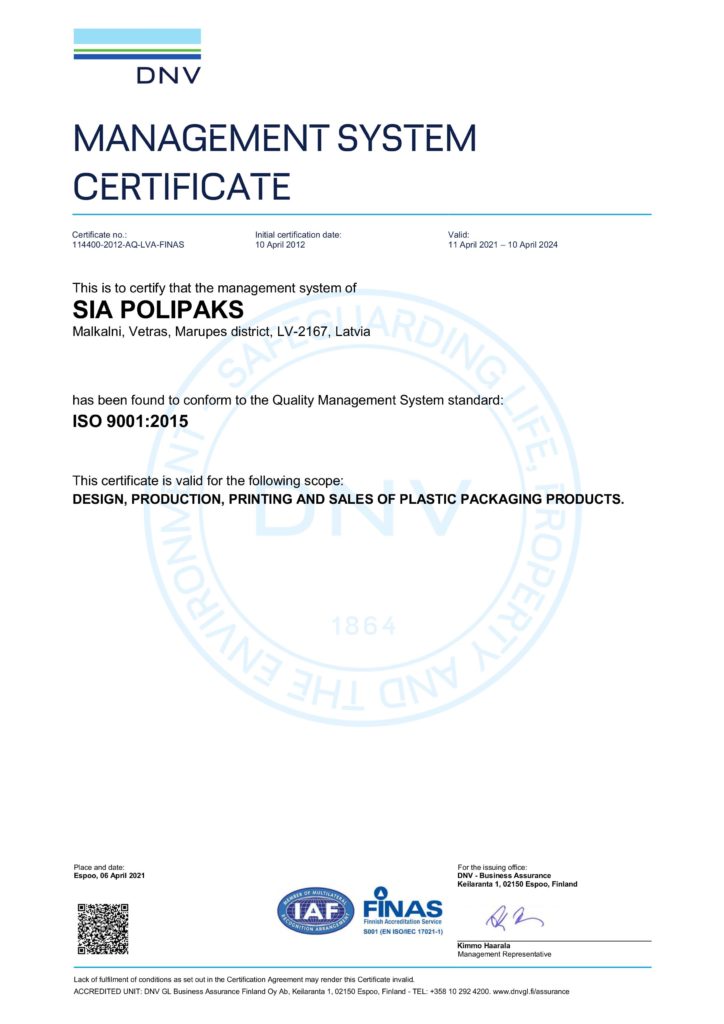

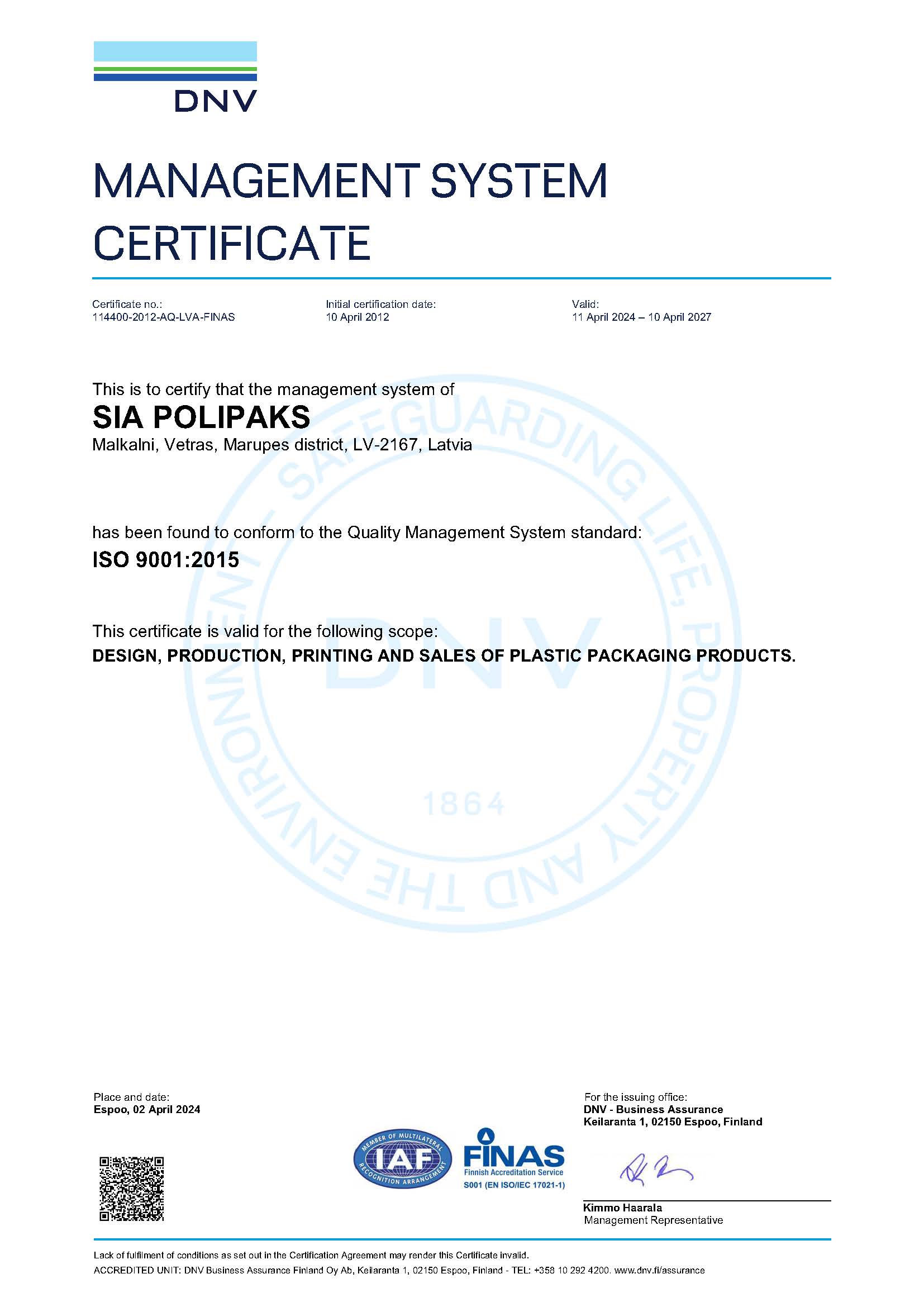

We have introduced a Quality Management System that has been certified in compliance with the ISO 9001 standard.

In the manufacturing of food packaging, an important factor in preventing the risk of food contamination is packaging safety. Our company has implemented a Hazard and risk management system, which includes the principles of hazard analysis and risk assessment (HARA).

Manufacturing processes are organized and controlled in compliance with good manufacturing practice, in accordance with the Commission Regulation (EC) No 2023/2006 Good manufacturing Practice (GMP) for materials and articles intended to come into contact with food.

We focus on the highest internationally recognized industry standards, so since 2016 the packaging production plant was certified in accordance with the BRC GS PACKAGING MATERIALS (BRC Global Standard – Packaging and Packaging Materials), which includes comprehensive requirements for management, quality and safety systems, processes, personnel, products and production environment.

Company since 2020, 7th October, has received CrefoСert Gold certificate issued by independent, objective finance company CREFO Rating ltd, proving that Polipaks ltd has excellent solvency. Received assesment has been approved by standard of Creditreform Risk Management in Germany.

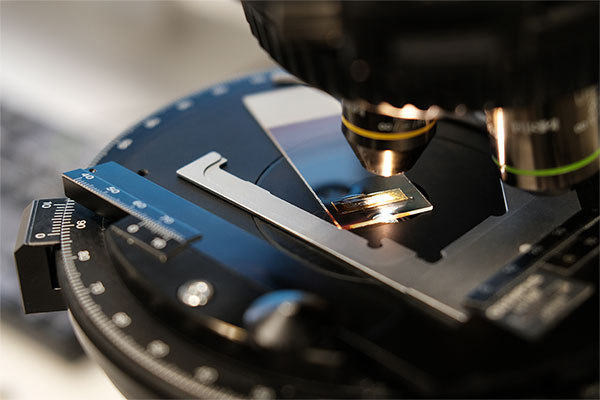

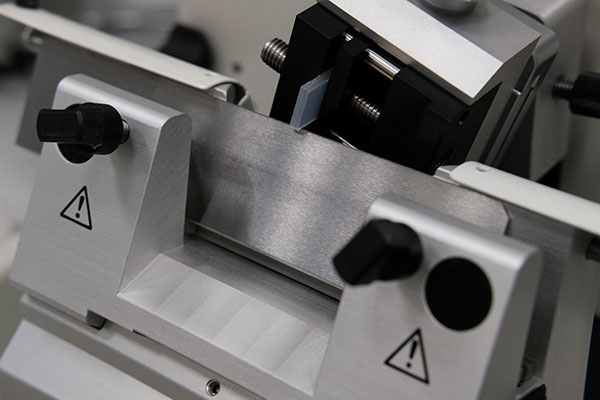

Laboratory

-

Laboratory checks physical and mechanical properties of the film or bag including: Tensile strength and Elongation at break, Puncture and Tear resistance, Sealing strength and others

-

To ensure the best quality and properties of the barrier films, we use standardized methods to check the film layers' thickness, Water Vapour Transmission Rate (WVTR) and Oxygen Transmission Rate (OTR)

-

Having printing and laminating equipment made it necessary for us to use gas chromatography analysis for residual solvents. Also we conduct checks on the ink adhesion to substrate (Tesa test) and coefficient of friction

-

Most of our methods are based on ISO or ASTM standards that can be declared in the Technical Data Sheets (TDSs) for our products

-

Laboratory checks physical and mechanical properties of the film or bag including: Tensile strength and Elongation at break, Puncture and Tear resistance, Sealing strength and others

-

To ensure the best quality and properties of the barrier films, we use standardized methods to check the film layers' thickness, Water Vapour Transmission Rate (WVTR) and Oxygen Transmission Rate (OTR)

-

Also we conduct checks on the ink adhesion to substrate (Tesa test) and coefficient of friction

-

Most of our methods are based on ISO or ASTM standards that can be declared in the Technical Data Sheets (TDSs) for our products

Innovations and Support

Pat Riley

Research & Development

The mission of R&D department is to innovate and discover new more eco-friendly, customer-oriented and efficient packaging options. In our research we often combine our efforts with our partners.

Seeking innovations and constant improvements in high definition printing technology and print quality.

Focusing our efforts on environmentally friendly and recyclable solutions that minimize environmental impact during production or in the product itself.

Working on reclosable, easy peel, thermal lamination film structures, haptic varnishes and innovative production methods.

Experts in barrier PE film that includes PA and EVOH combinations.

Technical Customer Support

Most of our products are designed for high performance automatic production lines, where the speed and consistency is the outmost necessity for successful operation. We supply film and bags to customers who use horizontal or vertical form fill seal, automatic bread packaging machines and many others.