Production

The latest technology, combined with innovation and professional expertise, drives our growth in production quality and efficiency. As a fully integrated flexible packaging producer with three decades of experience, we are committed to excellence.

Pre-Press

We have own pre-press department that specializes in artwork adaptation and colour separation for flexo print. Artwork checks and adjustments, print-proof printouts are all prepared in-house thanks to our team of highly skilled designers and modern software technology. Top quality platemaking on latest Esko HD flexo hardware and software is also available in-house.

File preparation

Our pre-press specialists adapt client layouts in accordance with the technical requirements to maximize the use of all flexographic printing capabilities

Full color print-proofs are available on customer's request

Color separation files are handled by latest Adobe and Esko certified software

Platemaking

We use Flat Top Dot (FTD) technology plates from world's leading manufacturers, that provide superior ink transfer, improve contrast, tonal range, making the print look great from the first impression to the last

Printing plates are produced with the help of the most modern UV exposure and solvent washout units from the world's top brands

File requirements

For best result please follow our recommendations

for the original layouts

Extrusion

Modern co-ex blown film extrusion lines with various options and over two decades of extrusion experience allow us to produce up to 9-layer films including barrier film combinations. We focus on delivering films with advanced properties such as high barrier, sealing, antifog, antistatic, and other mechanical and chemical enhancements.

Film thickness from 20 µm

Extrusion monthly capacity at 900 tonnes+

Specialist in mono and multilayer extrusion with our blown extrusion lines ranging from 1 to 9 layers

Raw materials only from trusted European suppliers

The implemented regranulation system allows us to reuse all PE-based production waste

Our database of approved extrusion recipes enables us to meet diverse industry requirements by producing a wide variety of packaging products for both food and non-food sectors.

We continuously strive to enhance and develop new solutions to address the diverse demands and requirements of the industry

Get more information about the films we produce!

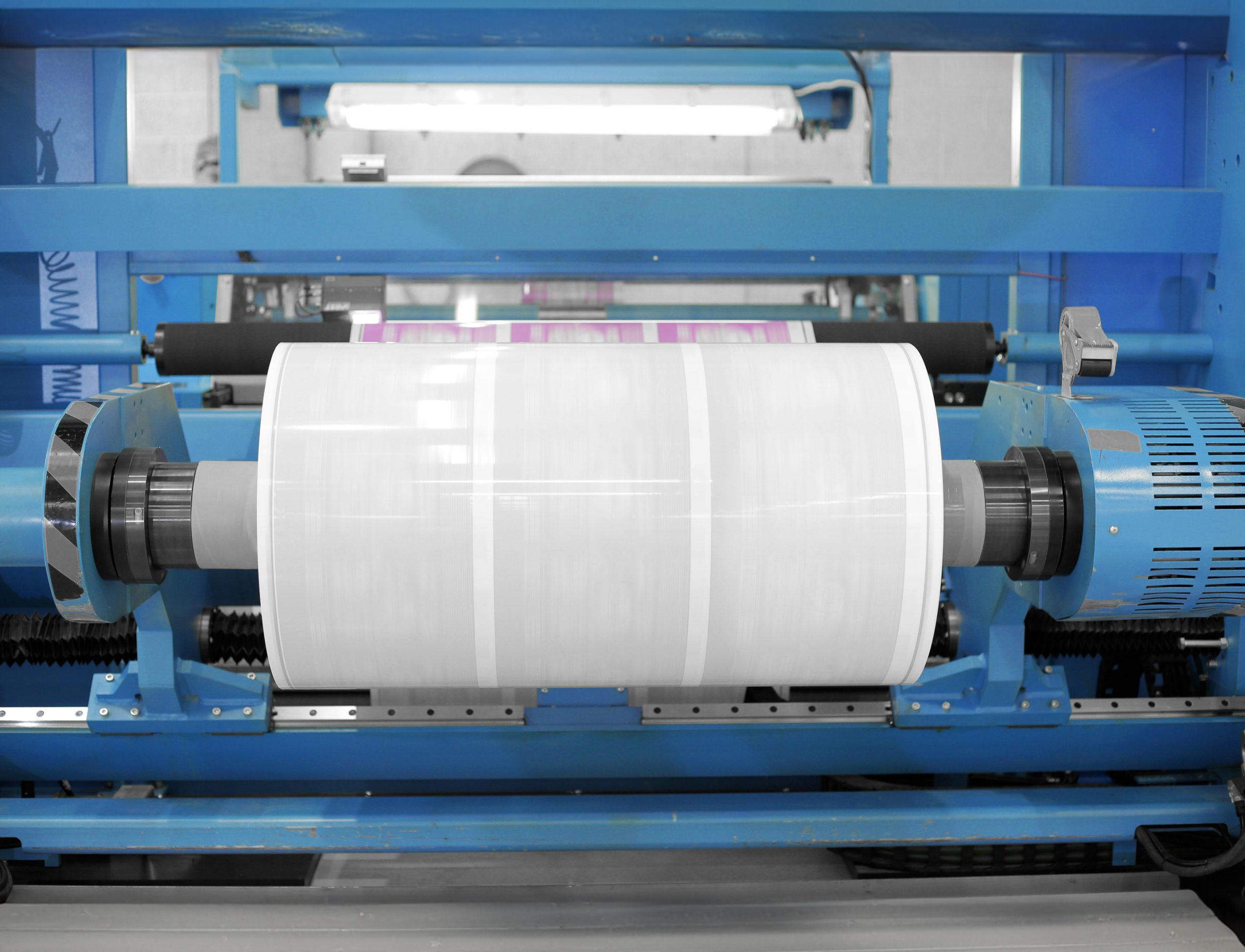

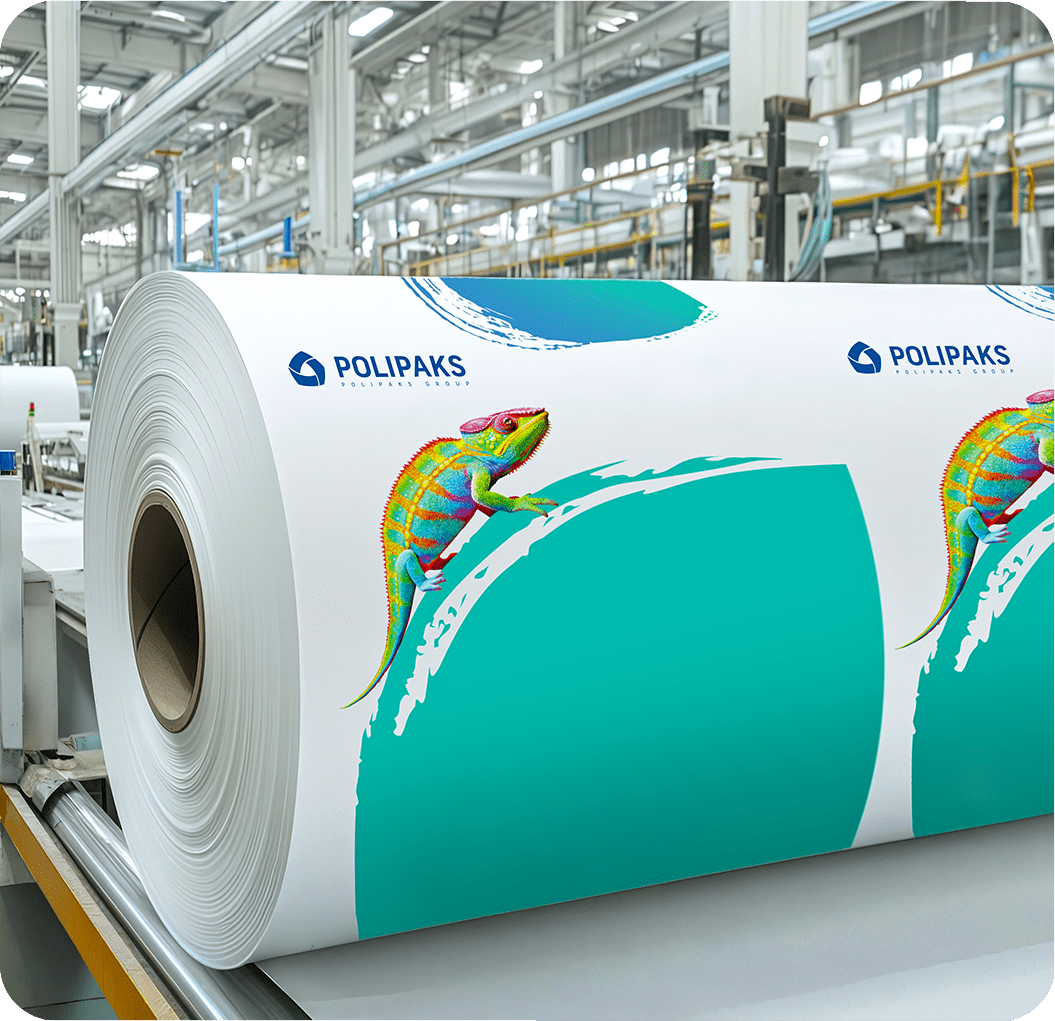

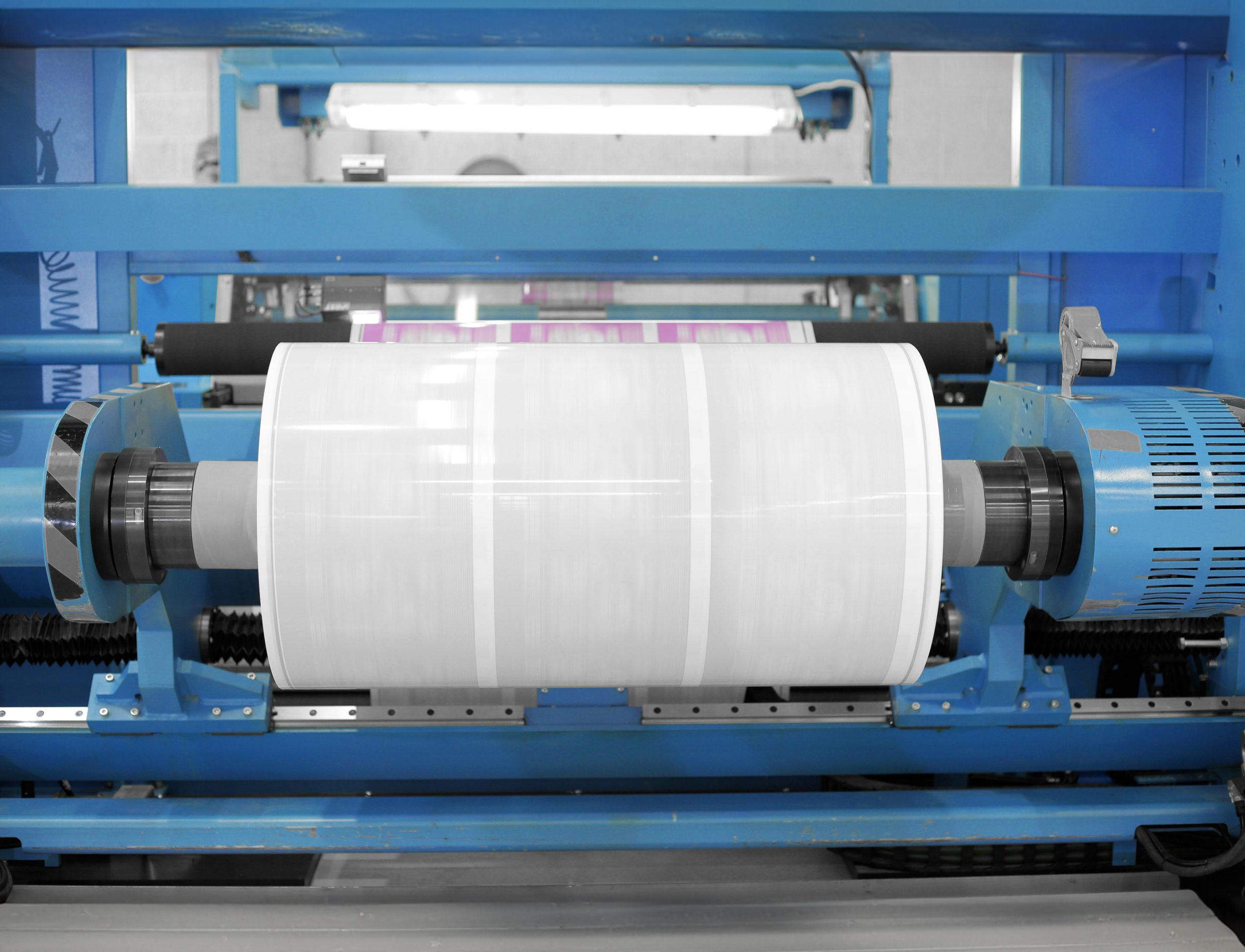

Printing

We offer a wide range of 10-color flexographic printing options, adhering to the highest quality standards with the support of 100% quality control cameras, automatic viscosity controls, and an automatic ink formulation station. Our extensive fleet of printing presses enables us to handle print runs of various sizes and repeats, all while maintaining uncompromised quality. Additionally, we offer the EG (Expanded Gamut) printing option to further enhance our capabilities.

Technical capabilities

From 1 to 10 printing colors available on the latest technology European flexo printing presses

Expanded Gamut (EG) printing teсhnology

Matt, gloss, antislip, paper-feel effect varnishes

Unic coding and numbering of each print repeat by Inkjet inline with print production of customer artwork.

Lamination

Solvent free and solvent based lamination with additional features like matt, antifog, cold seal can give your product the final appealing and distinctive look to stand out from the crowd on the store shelf.

Duplex or triplex lamination available for wide range of film combinations

Additional features for antifog, matt, gloss varnishes coating in register

Bag making

Wide range of bag-making equipment from world top equipment manufacturers provides our customers a large choice of bag shapes and sizes with extra options.

Array of possible add-on options

Different types of seals

Tear notch, various types of closures, euro holes, ventilation holes, embossing, etc.

Design for recycling structures (D4R)

Various handle types including cut and glued handles

Our product range includes 7 types of bags

Get more information about the bags we produce!

Wicket Bags

See product ↗Vacuum Bags

See product ↗Side Seal Bags

See product ↗Bottom Seal Bags

See product ↗Quad Seal Bags

See product ↗Stand Up Pouches

See product ↗Flat Bottom Bags

See product ↗

Slitting

We operate a fleet of modern slitting machines from top manufacturers equipped with microand macro-perforation capabilities, web folding options, and optical web alignment. This enables us to deliver smooth, high-quality production of reels tailored to customer specifications.

Up to 18 roll widths from one roll

Micro- and macroperforation options

Laser scribing